- Prioritize market research to understand industry trends, consumer preferences, and new technologies, guiding your entire production process to meet customer demands effectively.

- Master your supply chain by cultivating a network of reliable suppliers for essential components, ensuring a smooth and uninterrupted manufacturing process.

- Maintain unwavering commitment to quality by implementing stringent control processes at every production stage, bolstering your industry reputation and fostering customer loyalty.

- Navigate industry-specific regulations governing electronic products, as compliance is non-negotiable to avoid fines, recalls, and brand erosion while ensuring product safety.

- Design manufacturing processes with scalability and flexibility in mind, allowing you to adapt swiftly to shifting market dynamics and accommodate organic growth.

Prioritize Market Research

Engage in extensive market research to acquire an in-depth insight into your specific industry, encompassing the latest trends, evolving consumer preferences, and emerging technological advancements. This wealth of information will act as your beacon, illuminating your path during the entire production process.

Neglecting to comprehend your market fully can leave you aimlessly stumbling, resulting in the development of products that may ultimately fall short of satisfying customer requirements. To succeed, consistently monitor and adapt to the dynamic market landscape, ensuring your offerings remain aligned with ever-evolving customer demands.

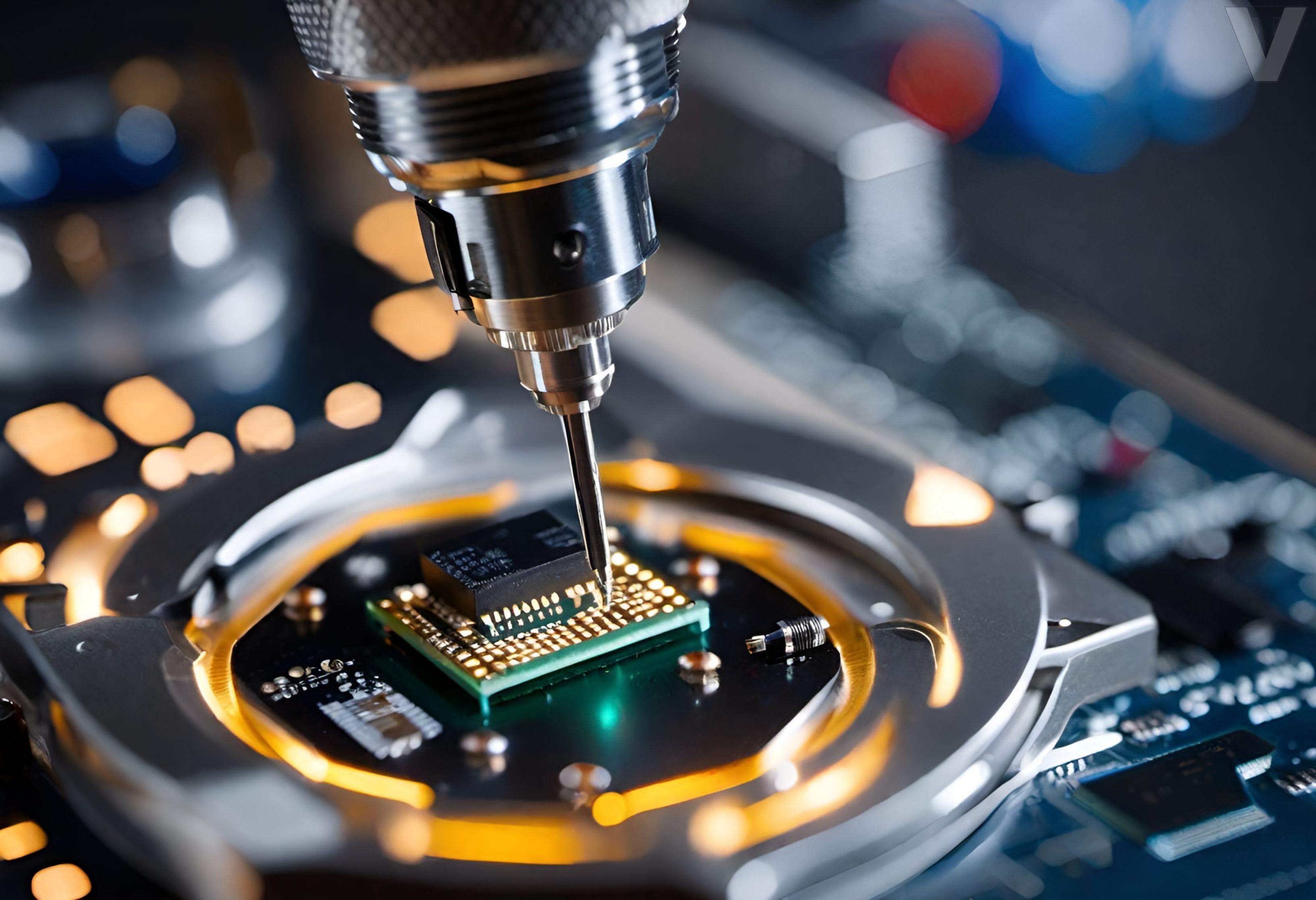

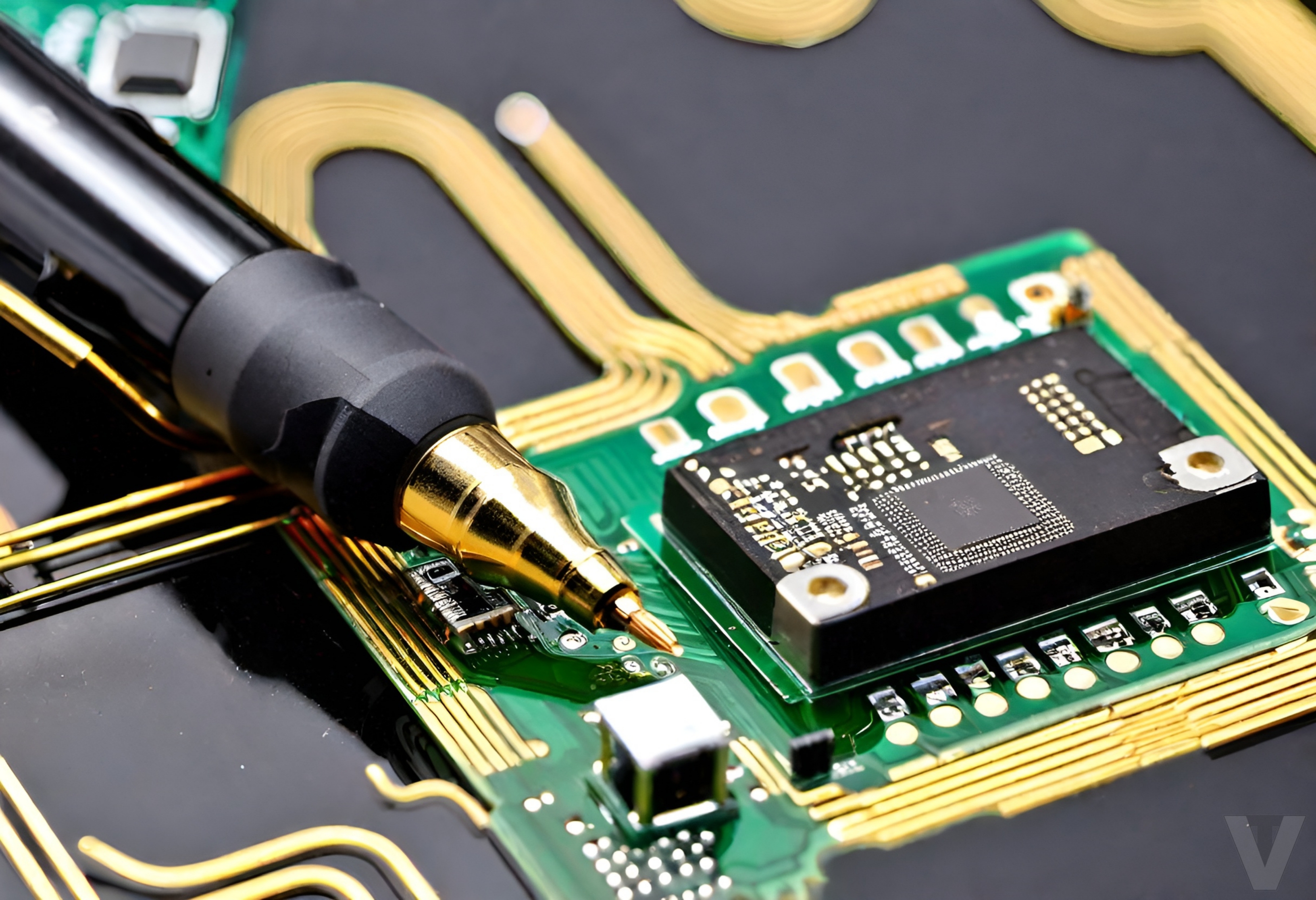

Supply Chain Mastery

Establishing an unshakable foundation for success hinges upon the meticulous management of your supply chain. To ensure a smooth and uninterrupted manufacturing process, one of the foremost imperatives is to cultivate a network of reliable suppliers for your essential components and materials. Not only is this not merely a logistical consideration, but it’s also a strategic choice that can have profound implications for your business.

Take, for instance, the procurement of critical components like small signal bipolar junction transistors; get more information here, since this is where the decision becomes paramount. Choosing suppliers that deliver essential products as well as real-time inventory updates from trustworthy international sources could be the key difference between achieving operational success and facing potential obstacles.

Quality Control Vigilance

Maintaining an unwavering commitment to quality is paramount. To achieve this, it’s essential to implement stringent quality control processes at every stage of production. Beyond simply meeting regulatory standards, these processes should be ingrained in your company’s DNA, reflecting a dedication to excellence that extends to every facet of your operation.

This meticulous approach doesn’t just ensure product reliability, it also plays a pivotal role in bolstering your reputation within the industry. A stellar track record for consistently delivering high-quality products not only attracts customers but also fosters trust and loyalty.

Regulatory Compliance Savvy

Dive deep into industry-specific regulations governing electronic products, for compliance is non-negotiable. Understanding the intricacies of these standards keeps your operations on the right side of the law, avoiding the looming specter of hefty fines, product recalls, and the erosion of your brand’s integrity.

Compliance isn’t merely a box to tick, it’s a shield that safeguards your business and ensures that your products meet the highest standards of safety and reliability. Staying ahead of the regulatory curve can also open up new markets and opportunities, making compliance a strategic asset that can drive innovation and long-term success.

Scalable Manufacturing

Adaptability is key to staying ahead of the curve across the landscape of electronics manufacturing. Therefore, design your manufacturing processes and equipment with scalability and flexibility in mind. This forward-thinking approach not only accommodates organic growth but also allows you to respond swiftly to shifting market dynamics.

The ability to ramp up production quickly in response to increased demand or pivot to meet changes in product specifications can give you a significant competitive edge. Scalable manufacturing also ensures you’re future-proofing your operations to thrive in an environment characterized by change and unpredictability.

Efficient Inventory Management

Effective inventory management is the linchpin that keeps your electronics manufacturing operations running like a well-oiled machine. Implementing an efficient inventory management system is essential to minimize waste and ensure the timely availability of materials.

Striking the right balance is crucial. Overstocking ties up capital and storage space, while understocking can lead to production bottlenecks and missed opportunities. Maintaining a well-calibrated inventory not only optimizes costs but also enhances the overall efficiency of your supply chain, ensuring that your manufacturing processes remain streamlined and responsive to market demands.

Continuous Process Optimization

To remain competitive and efficient, embrace a culture of continuous process optimization. Regularly evaluate and refine your manufacturing processes, seeking out opportunities for improvement. Complacency is the enemy of progress, and inaction can lead to stagnation.

In contrast, a commitment to continuous improvement fosters innovation and growth. It allows you to adapt swiftly to emerging technologies, market trends, and customer preferences. By fostering a culture of perpetual evolution, you position your electronics manufacturing venture not just to survive but to thrive in an ever-evolving landscape, where adaptability and innovation are the keys to long-term success.

In the world of electronics manufacturing, the path to entrepreneurial success is a challenging but immensely rewarding journey. The tips, advice, and insights shared in this article serve as a compass, guiding you through the complexities and nuances of this dynamic industry. From quality control vigilance to regulatory compliance savvy, from scalable manufacturing to efficient inventory management, and the commitment to continuous process optimization, these strategies form the pillars upon which you can build a thriving electronics manufacturing enterprise.

Curated and written by humans in their line of work and respective fields.

VitalyTennant.com is an informative business website, with a hint of entrepreneurship.