|

Getting your Trinity Audio player ready... |

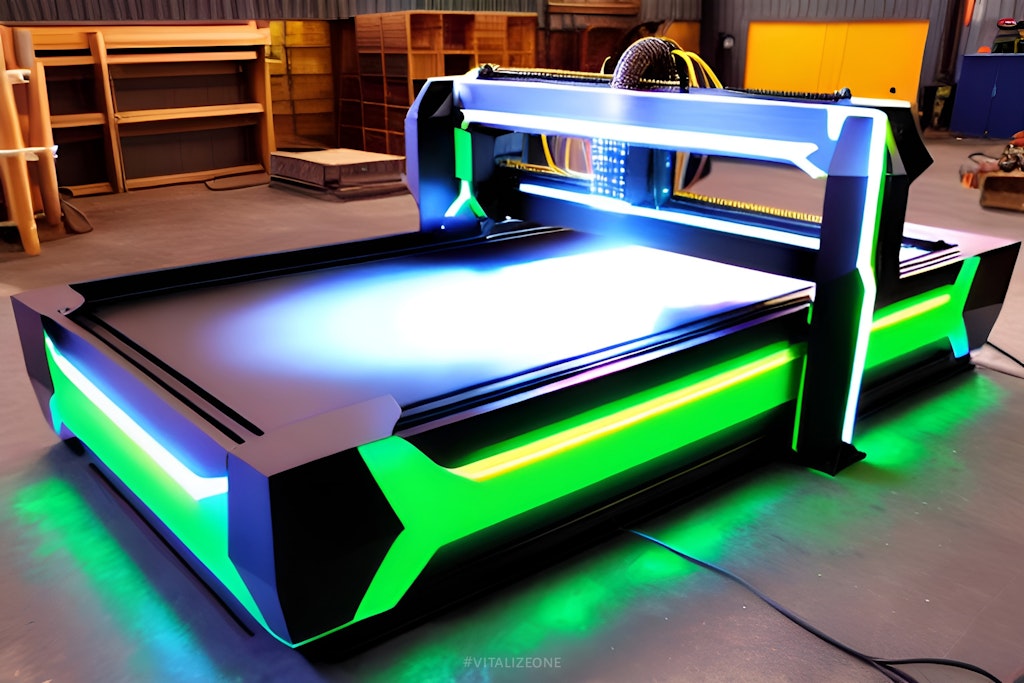

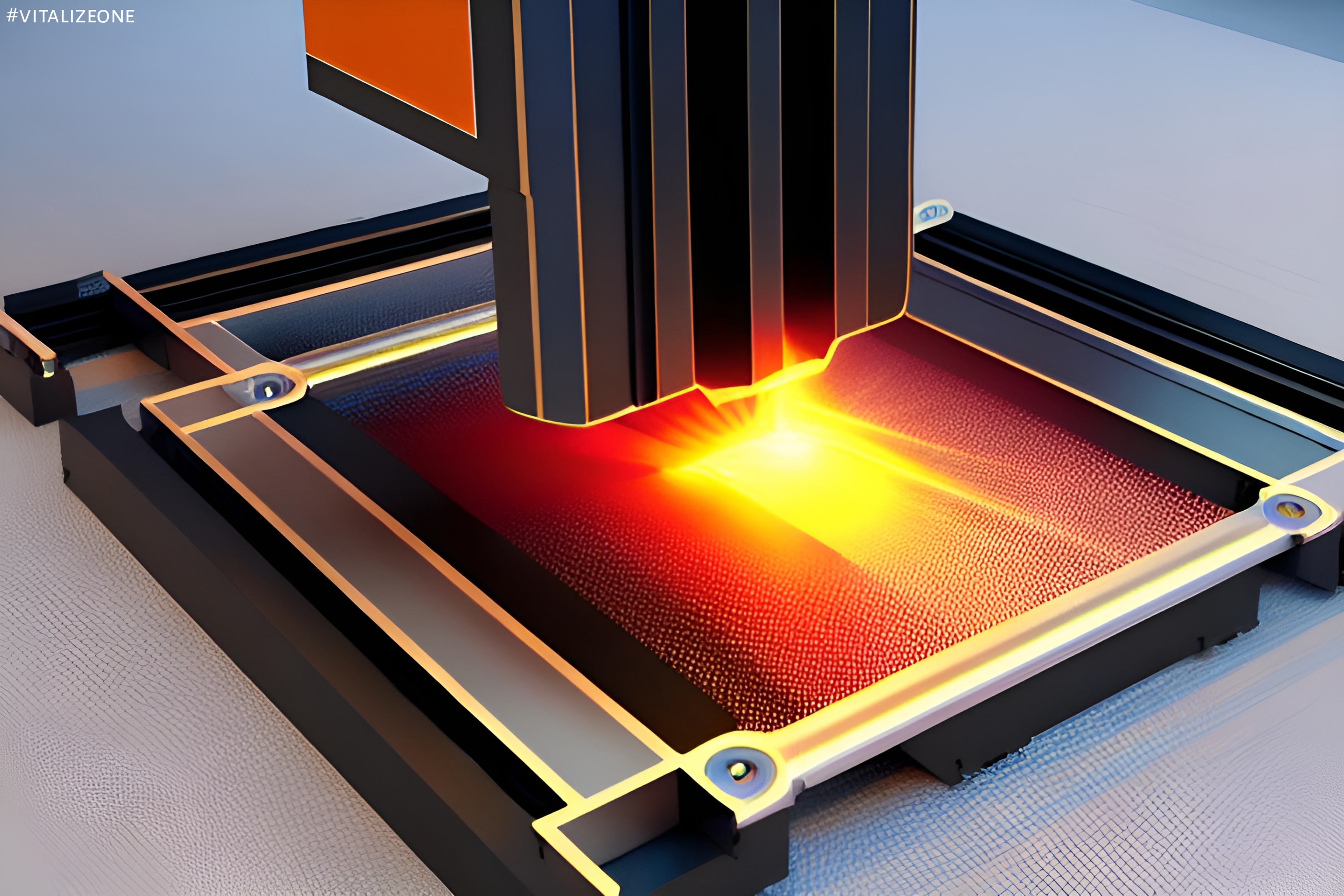

If you manufacture steel products in any industry, there is a long list of machinery that could be beneficial to your company. However, CNC plasma cutters are perhaps the most important of all.

The machines feature in manufacturing warehouses around the globe. Whether it’s agriculture, metal fabrication, or another business sector doesn’t matter. Here are six reasons to abandon outdated methods like grinders in favor of a plasma cutter.

#1. It’ll Boost Productivity Speeds

Every business decision is driven by the financial aspects. Unlocking increased productivity is a key step toward maximizing your profits. Removing warehouse inefficiencies is a priority for many business owners as they look to bump up their productivity. There is no question that CNC plasma cutters aid the speed of productivity.

A trained worker will be able to feed the piece of metal into the machine and complete the application in no time. There are many potential cutting applications to consider. But plasma cutting is always the fastest way to treat aluminum or steel. Regardless of how thick the material might be, this approach will allow workers to do far more.

This ensures that the cutter pays for itself in no time.

#2. Mistakes Are Removed

While fast speeds are desired, they count for very little if mistakes occur. Thankfully, advanced plasma cutter machines ensure that speed will not compromise accuracy. The use of modern CAD/CAM software, along with high-quality cutting materials, will ensure that accurate cuts are achieved. Time after time.

Conversely, manual methods and other metalwork solutions are likely to be burdened by human error. This translates to a waste of time, money, and materials. Furthermore, setting up jobs becomes a quick and easy process. This means your teams can get to work ASAP while even tiredness and other issues won’t cause poor finishes.

In turn, you will be left with quality products and happier customers.

#3. It’s A Greener Option

Plasma cutters do require electricity and gas to operate. Still, they consume less energy than many machines. More importantly, though, their accuracy means that your sheet metal will encounter far less waste material. So, you will find that using this method over outdated concepts actively reduces your carbon footprint.

Working with metallic materials is already better than many alternatives. When combined with the benefits of using super efficient machinery, your venture will be greener. Right now, this is highly desired by consumers and employees alike. When combined with other eco-friendly incentives, you will be positioned to celebrate your brand’s status.

Besides, it’s sure to remove any feelings of guilt that you may have previously had.

#4. They Create A Better Working Environment

Investing in better tools and equipment doesn’t only support the end product. It also makes life easier for workers. Metal work becomes less stressful and physically intense. Moreover, removing the fear of mistakes allows them to work more confidently. This naturally promotes a far happier setting, which means greater productivity. Statistically and anecdotally.

Similarly, there will be fewer arguments between different departments as there is no delay on the metalwork. Meanwhile, top range CNC cutting machines feature dust collectors. They will ultimately aid the air quality and protect worker health. It also reduces the cleaning duties, which is something all metalworkers will appreciate.

Happy working environments also see fewer staff absences.

#5. Plasma Cutting Opens The Door To More Products

Using plasma cutters won’t only allow you to improve your current output. It’ll additionally help you think about adding new products. That’s because plasma cutters can focus on more intricate shapes while also reducing the need for finishing. The precision and repeatability are not pessimistically affected by the choice of shape either.

The benefits of plasma cutting extend to the fact that it is possible to work with all metals. Flame cutting only works on ferrous metals for obvious reasons. So, if you’re eager to work with non ferrous materials like steel and aluminum, this move is highly advised. You can subsequently create more products for more industries.

Likewise, it can result in more durable products suited for extreme situations.

#6. It’s Safer

Finally, gas-powered plasma cutting uses gas that is not flammable. Therefore, it is the safer choice. In turn, this means that you can protect workers with greater ease, although safety gloves and goggles are still needed. It should also be noted that this can remove the threat of unscheduled downtime due to emergency responses.

The fact that it will protect your company finances by avoiding personal injury claims is a bonus. Above all else, though, it is a matter of satisfying your human responsibilities. The thought of being indirectly responsible for an injury or accident would cause sleepless nights. So, the switch will protect you too.

Once you embrace plasma cutting, you’ll never look back.